EPS at a glance

EPS is a widely used, lightweight foam packaging material that is made of 98% air and is 100% recyclable.

EPS packaging is so light that some call it ‘engineered air’

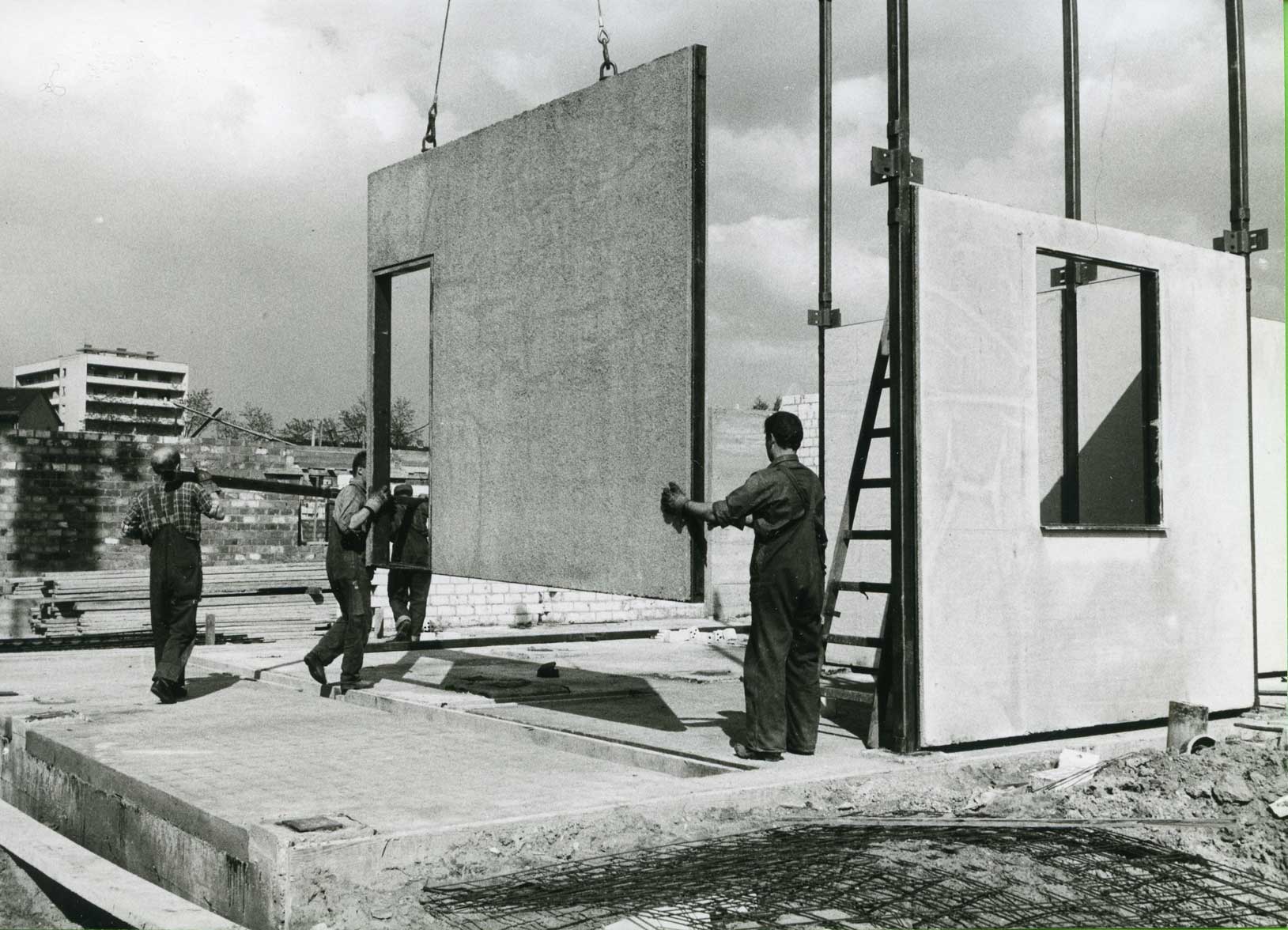

Invented in 1949 by Dr. Fritz Stastny, a scientist working at BASF in Germany, EPS has been used everywhere where light weight, shock absorption and insulation are critical, from electronics packaging to bicycle helmets and building insulation.

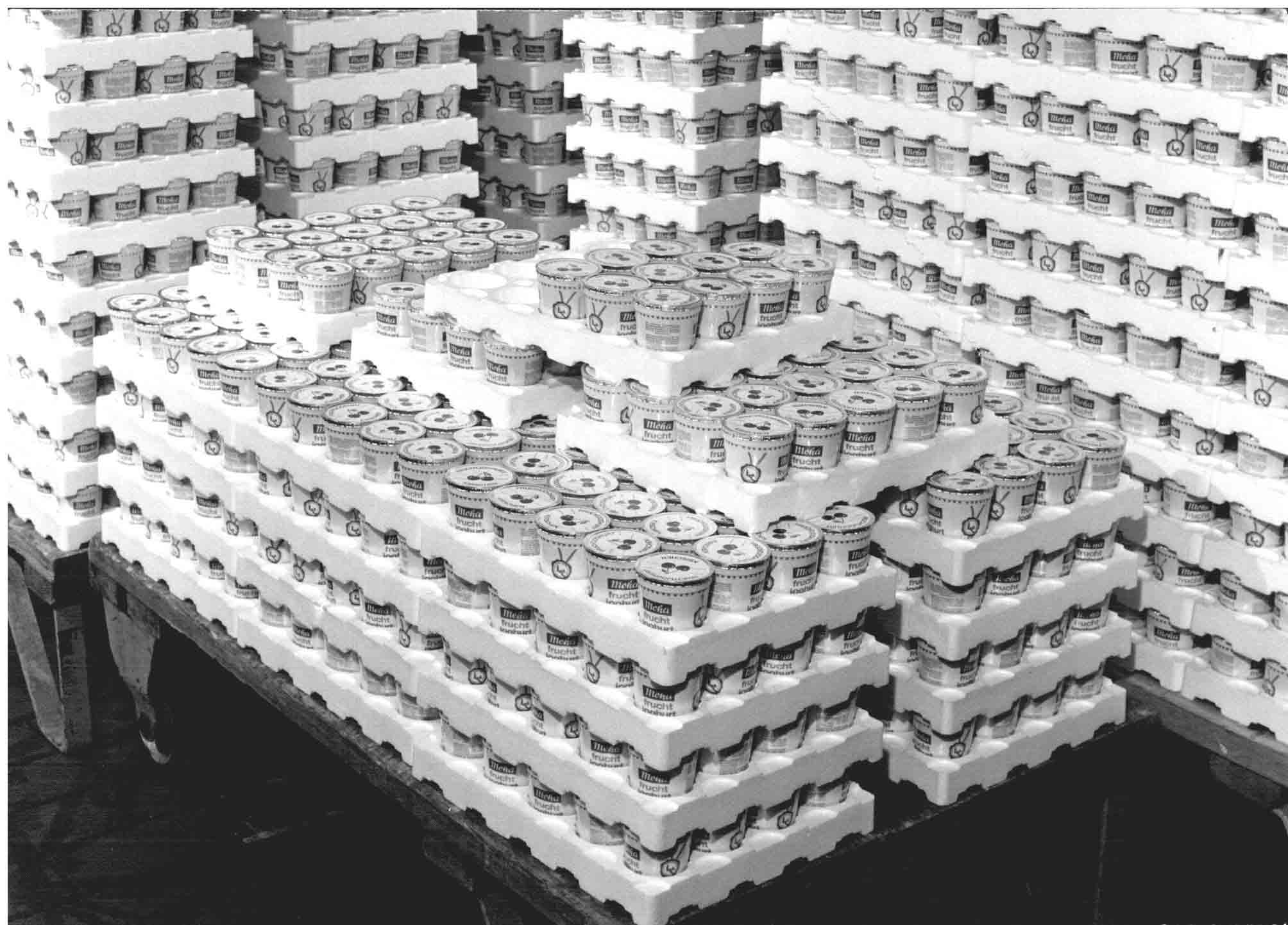

Some of the most important uses of EPS for packaging are fish boxes, electronics and white goods packaging and medical transportation including human organ transplants and COVID-19 vaccines. It is also widely used in bicycle helmets, children’s car seats and surfboards.

Because EPS is made from just one polymer, it is easy to recycle into new EPS or other plastic products.

The many names of EPS

Depending on where one lives, expanded polystyrene, or EPS, might be known by many different names.

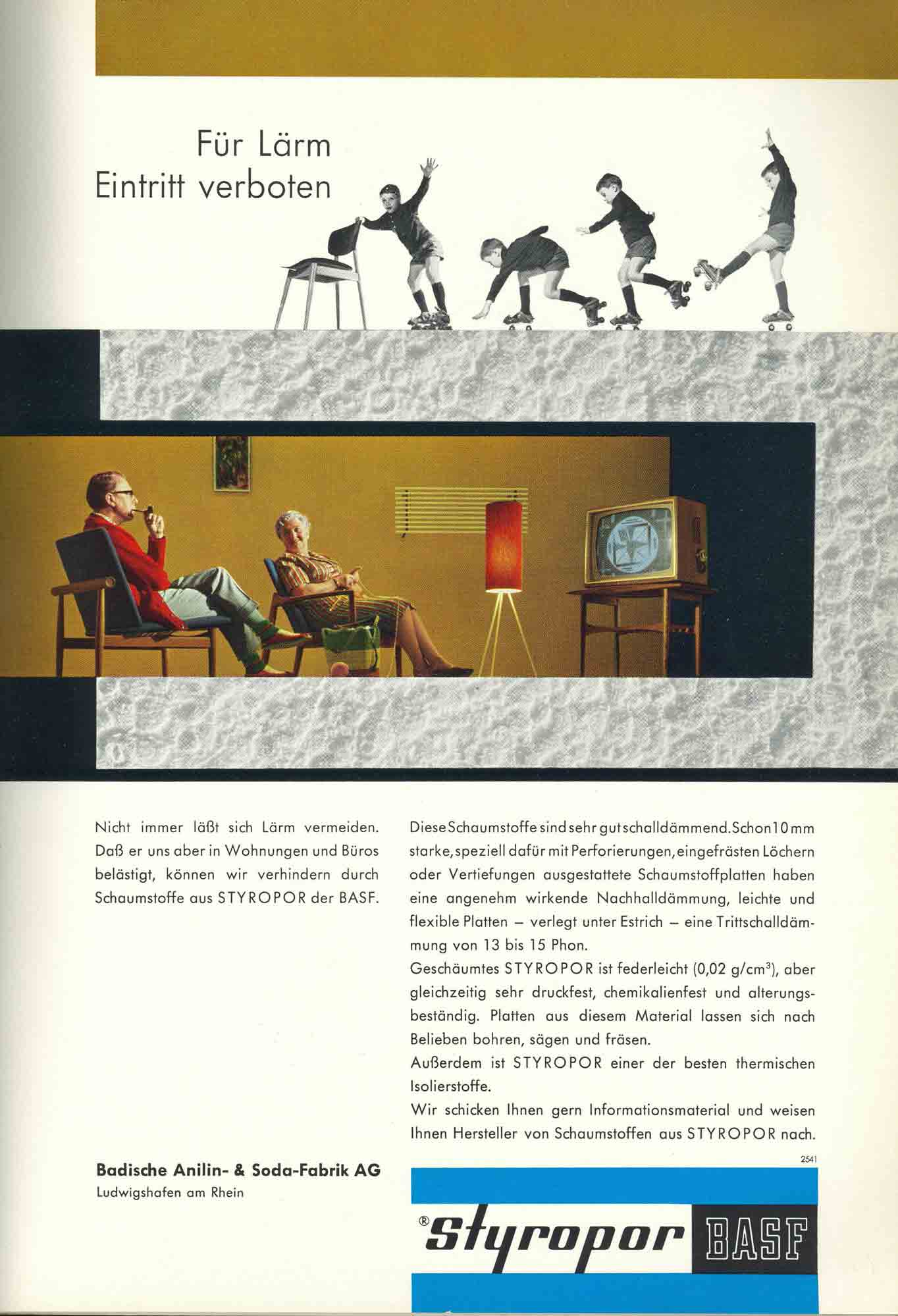

In addition to simple translations– polistirolo in Italian, poliestireno expandido in Spanish, polystyrène expansé in French and geëxpandeerd polystyrene in the Netherlands, EPS is also known as isopor in Brazil, esferovite in Brazil, by brand names including Styropor™, Airpop™ or Flamingo™, as well as by descriptive names such as engineered air, piepschuim or Quietschpappe, which means “squeaky package” in German.

Whatever you call it, EPS is one of the lightest, most versatile and most reliable protective packaging materials that exists.

Don’t confuse EPS with Styrofoam™ ! Although similar to EPS, Styrofoam™ is XPS – extruded polystyrene – and is made using a different process, put to different uses and often subject to different regulations.

How EPS is made

Expanded polystyrene, or EPS, is a rigid, lightweight, plastic foam produced from solid beads of polystyrene.

EPS is made by using steam to expand polystyrene beads that contain an expansion agent to a rigid cellular plastic with 40 times the original volume. Then, the resulting foam is moulded into a multitude of shapes, each suited to its specific application, further saving resources in the process.

Overall, EPS is 98% air, with the polystyrene encapsulating the air. This harnesses its value as an exceptional product for insulation and shock absorption. Its flexibility and adaptability, combined with its light weight, are among its most important qualities.

EPS helps deliver many of the things we enjoy in our lives: it is used for fish boxes, and packaging for electrical consumer goods as well as the shock-absorbing material in your bike helmet. And after its use, EPS is 100% recyclable and can be reclaimed for various purposes many times over.

These, and numerous other qualities, make EPS a very smart packaging product.

History

Expanded Polystyrene, or EPS, is a widely used plastic foam packaging and insulation material that has proven itself for decades.

EPS was invented by Dr. Friedrich (“Fritz”) Stastny, a scientist working at BASF, in 1949. His invention was patented as Styropor™ in 1952, a date that marks the beginning of the EPS success story.

Since then, research and consistent product development led to the EPS materials such as Neopor and Peripor, as also for other EPS applications, including in the construction sector.