News & Media

This is the place to find EPS packaging news,

views and answers to frequently asked questions.

Journalists and editors can contact our communications team

at media@smartpackagingeurope.eu

Blog

Check out the latest on EPS packaging and Smart Packaging Europe and its members here!

New Partnership to Map the Flow of Fish Packaging in Asia

Norwegian seafood industry partners to increase recycling of EPS fish boxes in Asia, promoting sustainability and circular economy solutions.

Update on The Ban on Styrenic Packaging in France

The European Commission has confirmed that the planned ban on non-recyclable styrenic packaging in France, set for 2025 under the Climate and Resilience Law, will not be enforceable.

How Ursula von der Leyen’s 2024–2029 Political Guidelines Impact the EPS Industry

Ursula Von der leye,

The Future of European Competitiveness: Key Insights and Opportunities for the EPS Industry

Learn how EPS industry supports Europe’s competitiveness through innovation, decarbonisation, and resilience, based on insights from Mario Draghi’s report

LCA Study Highlights Environmental Benefits of EPS Cooler Boxes

A detailed life cycle analysis (LCA) has compared the environmental impacts of small boxes made from cardboard and expanded polystyrene (EPS). The study shows that cardboard cooler boxes are not necessarily better for the environment than EPS cooler boxes. The findings indicate that while both types of boxes have an almost similar carbon footprint,

FranceAgrimer Publishes a Report on EPS in the Aquatic Sector

A recently published report by FranceAgriMer provides an in-depth analysis of the usage of Expanded Polystyrene (EPS) in the European aquatic industry. This extensive report, crucial for industry stakeholders, addresses the staggering annual influx of 35,176 tonnes of EPS into aquatic systems and explores effective recycling solutions and alternati

Finding the Right Balanced Approach for Transport Packaging

Explore the balance between sustainability and practicality in transport packaging with our article on crafting thoughtful reuse policies.

Sustainable Waste Management: Endorsing Amendments to the Waste Framework Directive

Learn about the EUMEPS initiative to support Amendments 291–294 & 465 of the WFD and how you can contribute to a more sustainable and circular economy.

Outcomes and Impact of UNEP INC‑3 in Nairobi

EUMEPS promotes EPS sustainability at UNEP INC‑3, advocating for future policies and challenging misconceptions.

AIPE’s Role in Advancing EPS Recycling within the Circular Economy

At the Ecomondo expo, AIPE forged partnerships and drove the circular economy forward by sharing EPS recycling with groundbreaking initiatives.

EPS is Recycled “at Scale and in Practice” Worldwide

The Ellen MacArthur Foundation acknowledges the impressive recycling rates of EPS packaging, reinforcing its sustainability credentials.

EUMEPS at UNEP Meeting: Advocating a for Sustainable EPS

EUMEPS contributed to shaping the plastic pollution policy at INC‑3, as an ideal partner for tackling environmental challenges in EPS circularity.

The plastic value chain gathers with MEP Engerer to discuss the proposed Packaging and Packaging Waste Regulation (PPWR)

The plastic value chain gathers with MEP Engerer to discuss the proposed Packaging and Packaging Waste Regulation (PPWR)

The Packaging and Packaging Waste Regulation (PPWR)

The Stakes of the Packaging and Packaging Waste Regulation (PPWR) for the EPS Industry

EPSolutely Event

EUMEPS and Smart Packaging Europe organised the event “EPSolutely! Innovation, recycling and the EPS industry’s progress towards circularity”

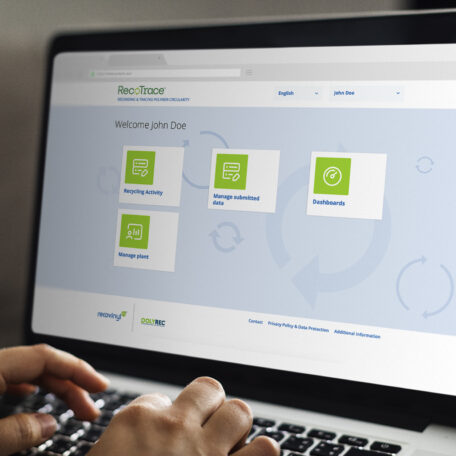

Press release: PolyREC launches RecoTrace

PolyREC launches RecoTrace, the multipolymer data collection system to record European recycled plastic data

A talk with the new EUMEPS Managing Director: the future of EPS in Europe

Jürgen gives his vision of the future of EPS in Europe

Celebrating Xmas with EPS

We bet that you didn’t know that EPS can be used to produce Christmas decorations. We can even create Christmas trees with it.

Ground-breaking facility to sort all household plastic packaging in Sweden

Site Zero will be the world’s most technologically advanced plastic recycling plant.

Let’s recycle!

Too many recyclable materials are not re-used across the EU. The efforts of the Circular Plastics Alliance (CPA) will boost plastic recycling.

Mission Is-possible: Industry focuses fight against beach litter

It is never good to see EPS on beaches, regardless of where it originates.

Lessons from Denmark

EPS is widely used in Denmark because of the country’s long tradition of fishing and aquaculture. And Denmark’s recycling numbers just keep on improving.

Lessons from the Far East

Japan leads the way with innovative ways to get end-of-life EPS to the recycling bin. More than 90% of used EPS is recycled in the country.

The EPS industry shifts to low carbon energy sources

Recently the EPS industry has taken drastic measures to ensure that energy used is as climate friendly as possible.

EPS or not EPS

Is it EPS or is it not EPS? That is a very good question. Because of this, we have recently published an infographic to explain this.

EPS art: Of “Styrobots” and stage sets

EPS is used by thousands of artists around the world to express their opinions and vision of the world.

Plastics industry produces statement on the publication of EU SUP Guidelines

Smart Packaging Europe co-signs a statement with 10 other organisations.

EPS, XPS, Styropor, Styrofoam? Keep your plastics straight, please!

European media and politicians seem confused when it comes to EPS.

EPS helps fishermen get their catch

EPS boxes offers excellent packaging for live worms, helping fisherman find more pleasure in their hobby.

EPS packaging keeps medication cool on long haul

A young traveller receives an emergency shipment of medicine in New Zealand in an EPS package.

EPS fish boxes keep fish fresh from port to market

Their light weight, combined with superior thermal insulation properties, reduces the need for cooling.

Hello, world!

Today marks the official launch of Smart Packaging Europe.

Twitter Feed

We’re an alliance of companies with the mission to contribute to a more circular, sustainable economy by raising awareness of the benefits of EPS packaging.

FAQs

Here you can find answers to some of the most frequently asked questions about EPS in one place.

1 | What is expanded polystyrene (EPS)?

Expanded polystyrene, or EPS, is a widely used plastic foam. Thanks to its versatility, cost-effectiveness, light weight, and excellent insulation and shock-absorbing properties, it has been many companies’ packaging material of choice for more than 50 years. EPS can be found in a wide range of everyday applications from fish boxes to motorcycle helmets as well as a protective packaging for heavy items such as refrigerators.

This innovative material was developed in 1949 by Dr. “Fritz” Stastny, a scientist working at BASF in Germany. His invention was patented in 1952, and this date marked the beginning of the success story of a foam that we can no longer imagine doing without in our everyday lives. In fact, people in many countries know EPS by different names including Styropor, Airpop and Flamingo.

2 | What is polystyrene foam?

The term polystyrene foam can be used to refer to two types of materials that have similar properties but which are the result of two different production methods with different properties and uses. One is Expanded polystyrene (EPS) while the other is Extruded Polystyrene (XPS).

Styropor™ is a trademark that belongs to BASF and refers to EPS. Styrofoam™ is a registered trademark that belongs to Dow Chemical and is made of XPS.

Each has properties that makes it the best and most sustainable material for the applications where it is commonly used. That often gets lost in emotional public debates about plastic litter and creates a problem when policymakers and others sometimes blame the wrong plastic and make decisions with unintended consequences.

3 | How is EPS made?

EPS is derived from a raw material consisting of solid beads of polystyrene with added pentane, known in the trade as granulate. When steam is applied to the raw material, it expands. This makes the gas expand and form closed cells of EPS which occupy approximately 50 times the volume of the original polystyrene bead. This would be the equivalent of a tennis ball becoming the size of a basketball. When expanded, EPS consists of 98% air and 2% polystyrene. Because it is a single polymer material, it is easy to recycle.

4 | Where is EPS packaging used?

EPS can be found in diverse formats due to its versatility and distinctive properties. Its insulating properties allows it to serve as the material of choice to package fruits and fish to reduce their spoilage, for instance, or to transport highly fragile human organs. EPS also serves as packaging for many heavy white goods and electronic and electric (E & E) devices due to its high shock absorption and adaptability to be moulded to any shape required and lightness. EPS is also one of the most-widely used building insulation materials and used in many other specific applications.

5 | What are the functional benefits of using EPS for packaging?

Damage avoidance is a top priority when transporting high-value, fragile items such as white goods. EPS has demonstrated in drop tests, vibration tests and other performance data that it provides the best protection due to its exceptional and distinctive cushioning properties. Smart packaging design and the versatility of the material also mean that it can be moulded to different sizes, strengths and performance levels to protect those part of the product that are more critical and could be subject to wear during transportation, saving packaging time and costs. The rigidity and strength of EPS means that EPS packed goods can also be stacked up to maximise vertical warehouse space, boosting capacity and efficiency.

6 | What are the environmental benefits of EPS?

Because EPS consists of 98% air, it is resource-efficient by nature. The air contained in the closed cells allows for maximum performance when it comes to shock absorbance and insulation at a very light weight. This reduces CO2 emissions during transport. Its extraordinary insulation properties, EPS boosts energy saving in its many applications, both construction and packaging. Such properties have been demonstrated thoroughly and several comparative analyses that EPS outperforms other packaging (and insulation) materials.

Moreover, EPS can be fully recycled without deterioration and come to life repeatedly. The European EPS industry has been actively involved in setting up collection points to boost this and ensuring the uptake of recycled EPS.

7 | What does the industry do to increase resource-efficiency?

With the production of expanded polystyrene, the industry increases resource efficiency as we reduce the amount of oil that we consume. Although virgin polystyrene is a fossil-based product, only a small amount of raw material is required to produce EPS. This is because EPS effectively consists of 98 % air and only 2 % polystyrene, the cells which contain the air. Out of every litre of oil used to manufacture EPS, up to 200 litres of oil is saved over the life of the product. The EPS industry has been using all means to increase re-use, e.g. by-products of the production process in the same process, to further increase resource efficiency.

8 | Is EPS packaging re-usable?

Yes, EPS packaging can be re-used multiple times, where in particular product safety and food hygiene rules allow it. Common examples include insulating boxes in the food service and catering sectors.

9 | Is EPS recyclable?

Yes, EPS is 100% recyclable, and it is recycled throughout the world. In 2017, recycling rates for EPS post-consumer packaging waste exceeded 52% in Belgium and Norway, 47% in the Netherlands, 46% in Germany, and 38% in Italy, showing that EPS recycling is economical. EPS is an environmentally friendly plastic, worth collecting and easy to identify during separate collection and sorting. Different compaction solutions are available, depending on the desired output. There are many ways to recycle EPS, such as mechanical, physical (dissolution) and chemical recycling. The European EPS industry was one of the first to submit a recycling pledge to the European Commission and now actively contributes to the Circular Plastics Alliance (CPA) to collectively achieve the goal that 10 million tonnes of recycled plastics are used in European products by 2025.

Click here to learn more about EPS recycling in the EU.

10 | How do I dispose of EPS packaging waste correctly?

EPS waste is a valuable material that must always be responsibly handled. In principle, EU law already obligates EU Member States to separately collect all plastic waste (including EPS). Unfortunately, this is still not the reality everywhere. However, this is finally starting to change, and more and more countries are collecting and thus facilitating the recycling of post-consumer EPS packaging waste, creating a growing supply sought after recycled EPS. Besides curbside pickup, municipalities in some countries, as well many EPS production facilities and many of the important commercial EPS users, operate collection points. Many white goods retailers take back their EPS packaging after delivery. Even where EPS waste is not separately collected, it can be sorted from mixed waste for recycling. Chemical recycling even allows the recycling of mixed plastic waste.

11 | Does EPS contribute to litter in the environment?

The EPS industry has been reviewing the evolving research on plastic (and other) litter and actively fights any littering of the environment – be it of valuable materials like EPS or of any other material.

EPS floats on water surfaces and is easily recognisable, although it is still sometimes confused with other plastic foams. It is not the primary component of marine debris in the water column and on the seabed. Furthermore, item counts do not reflect the mass of any pollutant in the environment. Even when using item counts, less than 1% of all litter found on EU beaches have been clearly identified as polystyrene (cf. European Commission, Impact assessment for the ‘Single-use Plastics Directive’, SWD(2018) 254 final, part 2, pp. 31 et seq., categories ranking 28 and 53). However, polystyrene in itself is already a broader category that includes EPS, but also other forms of polystyrene.

In 2019, the Swiss Federal Laboratories for Materials Science and Technology found in a study for the Federal Office for the Environment that EPS is actually the least littered of seven major plastic materials, having a so-called emission factor of 0.037 ± 0.012%. The emission factor is the share of EPS consumed leaked into the environment.

12 | How does the industry protect the environment?

The EPS industry is fully committed to protecting the environment, including the marine environment, from any negative impacts. To this end, the industry has been engaged in many initiatives, e.g.:

- EUMEPS’ packaging division Power Parts is a partner of Operation Clean Sweep (OCS). OCS is working on preventing the leakage of plastic pellets during production, handling, transportation, conversion, and recycling across Europe.

- Smart Packaging Europe’s supporters Storopack and BASF broke new ground in 2019 by using material from an innovative recycling process to produce EPS fish boxes and other insulative food packaging. Complementing other, well-established recycling options for EPS, the process allows for the recycling of mixed plastic waste.

- In Italy, Spain, Portugal, Greece, and beyond, the LIFE-funded project, EPS-SURE has demonstrated that it is technically, environmentally, and economically viable to collect, store, pre-treat (compaction, briquetting, washing), and recycle waste EPS fish boxes into new PS food contact packaging. Thus, it has closed the loop and overcome challenges that any comparable material used for fish boxes faces. Although the final results have not yet been published, the expected outcome is the reduction of the landfilling of waste EPS fish boxes by 80% in some European countries (70% in Spain and 50% in Italy and Greece).

- In Greece, EUMEPS’ national association, EPS Hellas, supports an initiative led by the non-profit organisation Archipelagos Institute of Marine Conservation to put in place an experimental net for the cleaning of surface waters from plastic waste.